PLATINUM 100

PLATINUM 100 is our innovative large-area panel formwork for walls

PLATINUM 100 generates appreciably lower labor and life-cycle costs than traditional formwork systems. It requires up to 30% less ties up to a height of 3.60 m and delivers high occupational safety as well as high quality concrete surfaces.

Product advantages

Work safely

- Connection elements are secured inside panel during transportation

- High concrete pressure up to 100 kN/m² for safe and fast concrete placement

- Safe pouring with system platform

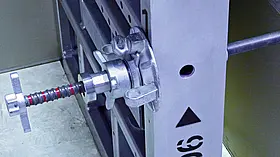

- Aligning wedge clamps are secured in the panel and deliver tight and flush joints

- RFID chips on all sides for easy, fast and individual panel identification, also in stacks

Work productively

- Up to 3.60 m high panels to match increased wall heights

- One tie row less is required for pouring heights of up to 3.60 m compared to traditional systems; 30% less ties

- High quality concrete finish reduces amount of rework

- One-man tie operation saves time and money

- 100 kN/m² concrete pressure throughout the system for new SCC and liquid concrete types

- Neatly aligned tying and joint grid possible, no matter if the panels are used in upright or horizontal positions

- High-quality concrete finish

- Complies with DIN 18202, line 7

- The aligning wedge clamp integrated into the formwork can only

be mounted in the correct position thanks to the steel cable safety

system - Specified tensioning points that guarantee anchoring at the

structurally intended positions

Application & use

Download the user guide here. Click on the name of a chapter to access it directly.

Overview of user guide

Technical data

| Panel widths | 45 | 60 | 75 | 90 | 120 | 240 cm |

| Panel heights | 60 | 90 | 120 | 300 | 360 cm |

| Multipurpose panels | 105 x 90 | 105 x 120 | 105 x 300 | 105 x 360 cm |

| Profile thickness | 14 cm steel frame profile (closed) |

| Form lining | ECOPLY full plastic composite sheet |

| Lining thickness (coating) | ECOPLY 15 mm | (300 μm thick PP surface) |

| Average weight | 65 to 90 kg/m² (including connection parts) |

| Max. concrete pressure | 100 kN/m² (DIN 18202, line 7) |

| Relevant standards | Complies with DIN 18216 | EN 1993 |

| Standard connection | PLATINUM aligning wedge clamp |

| Corrosion protection | Fully galvanized |

| Inner corners | MP inside corner | Inside corner 90° (2.5° play for easing) |

| Outer corners | MP panel with basic panel (90°) |

| Special features | • Only one type of tie required for wall thicknesses from 15.00 – 42.50 cm • Versatile platform and access system with integrated backrailings, side rails, self closing passages and ladders • RFID chips for individual panel identification • Hinged inside and outside corner • Simple turning of the panels thanks to a crane sling, which is easy to handle. |

Downloads

Question not answered yet? We are here to help!

The fields marked with an * are mandatory and must be filled out.